The shell and tube heat exchanger is named for its two major components – round tubes mounted inside a cylindrical shell.

The shell cylinder can be fabricated from rolled plate or from piping (up to 24 inch diameters). The tubes are thin-walled tubing produced specifically for use in heat exchangers. Other components include: the channels (heads), tube sheets, baffles, tie rods & spacers, pass partition plates and expansion joint (when required).

Details

Tubes

Tubing may be seamless or welded. Seamless tubing is produced in an extrusion process; welded tubing is produced by rolling a strip into a cylinder and welding the seam. Welded tubing is usually more economical.

Normal tube diameters are 5/8 inch, 3/4 inch and 1 inch. Tubes of smaller diameter can be used but they are more difficult to clean mechanically. Tubes of larger diameter are sometimes used either to facilitate mechanical cleaning or to achieve lower pressure drop.

Tube sheets

Tube sheets are plates or forgings drilled to provide holes through which tubes are inserted. Tubes are appropriately secured to the tube sheet so that the fluid on the shell side is prevented from mixing with the fluid on the tube side. Holes are drilled in the tube sheet normally in either of two patterns, triangular or square.

The distance between the centers of the tube hole is called the tube pitch; normally the tube pitch is 1.25 times the outside diameter of the tubes. Other tube pitches are frequently used to reduce the shell side pressure drop and to control the velocity of the shell side fluid as it flows across the tube bundle. Triangular pitch is most often applied because of higher heat transfer and compactness it provides. Square pitch facilitates mechanical cleaning of the outside of the tubes.

Applications of Shell and Tube Heat Exchanger

The shell-and-tube heat exchanger is by far the most common type of heat exchanger used in industry. It can be fabricated from a wide range of materials both metallic and non-metallic. Design pressures range from full vacuum to 6,000 psi. Design temperatures range from -250°C to 800°C. Shell-and-tube heat exchangers can be used in almost all process heat transfer applications.

The shell-and-tube design is more rugged than other types of heat exchangers. It can stand more (physical and process) abuse. However, it may not be the most economical or most efficient selection especially for heat recovery applications or for highly viscous fluids. The shell-and-tube heat exchanger will perform poorly with any temperature crosses unless multiple units in series are employed. Typical applications include condensers, reboilers and process heaters and coolers.

India. Manufactures broad range of heat transfer equipment. Includes automotive and industrial radiators, air cooled and shell and tube heat exchangers, finned heat exchanger tubes, oil coolers, and waste energy recovery units. UK. Manufactures broad range of heat exchangers and water heating units. Includes plate, shell and tube, multi scrape, and corrugated tube models. Site provides detailed product information and offers downloadable newsletter. Service company specializing in repairs, rebuilds, retubing, cleaning, and inspection of commercial and industrial heat exchangers. Units handled include plate and frame, shell and tube, and fin fan types.

Design and manufacture of heat transfer equipment. Products include shell and tube, plate and frame exchangers, heating and cooling coils, tankless coils, oil preheaters, water heaters and tube bundles. Manufactures broad range of heat transfer equipment for refrigeration, marine, and industrial process applications. Includes shell and tube, plate and frame, and shell and plate heat exchangers, as well as chillers and oil coolers. India. Manufactures broad range of heat transfer equipment. Includes automotive and industrial radiators, air cooled and shell and tube heat exchangers, finned heat exchanger tubes, oil coolers, and waste energy recovery units.

Full service manufacturers of flexible core heat exchangers, designed for heavy duty cooling and heating applications. Products include engine radiators, oil and charge air coolers, and tube and shell models. Design and manufacture of heat transfer equipment. Products include shell and tube, plate and frame exchangers, heating and cooling coils, tankless coils, oil preheaters, water heaters and tube bundles. India. Manufactures broad range of heat transfer equipment. Includes automotive and industrial radiators, air cooled and shell and tube heat exchangers, finned heat exchanger tubes, oil coolers, and waste energy recovery units.

Design and manufacture of heat transfer equipment. Products include shell and tube, plate and frame exchangers, heating and cooling coils, tankless coils, oil preheaters, water heaters and tube bundles. India. Manufactures broad range of heat transfer equipment. Includes automotive and industrial radiators, air cooled and shell and tube heat exchangers, finned heat exchanger tubes, oil coolers, and waste energy recovery units. Educational software for shell and tube heat exchanger simulations.

Korea. Manufactures broad range of heat exchangers. Includes finned tube, gasketed plate, shell and tube, and spiral models. Also offers recuperators and deaeroators. Distributes broad range of heat exchangers. Includes brazed, plate, shell and tube, and spiral models, available in standard and custom configurations. Also sells parts and provides reconditioning services. Designs, sells, and repairs heat exchangers. Includes shell and tube, plate and frame, brazed or welded plate, air cooled, and spiral models.

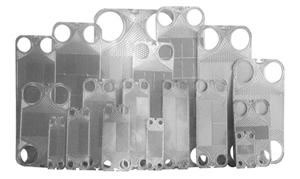

Plate Heat Exchanger

Plate Heat Exchanger

Gasketed Heat Exchanger

Gasketed Heat Exchanger

Welded Heat Exchanger

Welded Heat Exchanger

Brazed Heat Exchanger

Brazed Heat Exchanger

Spiral Heat Exchanger

Spiral Heat Exchanger

Plate and Shell Heat Exchanger

Plate and Shell Heat Exchanger

Plate Evaporator and Plate Condenser

Plate Evaporator and Plate Condenser

Sub-station System for District Heating and Cooling

Sub-station System for District Heating and Cooling

Maintainance Spare Parts

Maintainance Spare Parts

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System