Plate Evaporator |

|

|

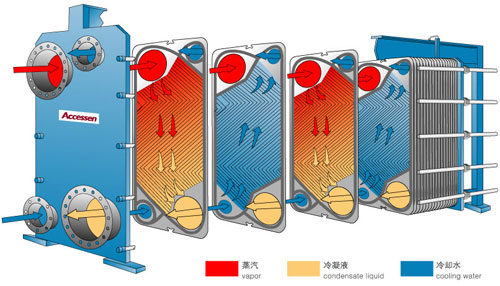

Introduction of Plate EvaporatorLantoky plate evaporator is designed based on shell and tube evaporator and adopted from the advantages of plate heat exchanger. |

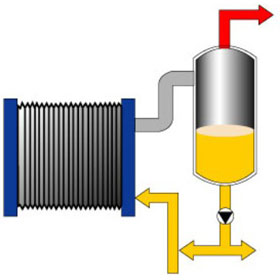

Working PrincipleLantoky plate evaporator is designed for evaporation, there are two small inleter and one big outlet, one big inlet for vapor heating and one small outlet for vapor and condensed water.Our plate evaporator adopts the concept of plate cluster and every plate cluster composed of butt welded plates or demountable plates. Heated vapor condensate in welded pass and stuff will be evaporate and condensate in gasket sealed pass. |

|

Plate Condenser |

|

|

Introduction of Plate CondenserLantoky plate evaporator is a tailor-made product for condensed vapor under condition of low pressure or vacuum in evaporation and distill systems. Lantoky plate condenser can meet specific application and capacity requirements. |

Working PrincipleLantoky plate condenser is specially developed for vacuum condition. It contains a big inlet for vapor and a small outlet for condensate liquid. The plate Condenser is composed of plate cluster of butt welded plates or demountable plates.The plate is developed for best effectiveness of condensation. The passes are separately into wide pass (vapor side) and narrow pass (cooling water side), which can maintain a very low pressure on vapor side and turbulence on cooling water side. Therefore, it can achieve highest heat transfer efficiency and least fouling. |

|

Operation Mode of Plate Evaporation |

|

|

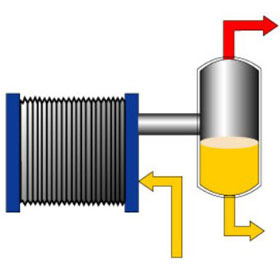

Direct EvaporationBecause of conception of rising film and high turbulence, plate evaporator provides excellent wetting ability and can adopt direct evaporation. In the system of parallel flow evaporator, pump is not required; in the system of counter current flow, transfer pump can be used instead of circulating pump, at mean time, staying time is short. |

|

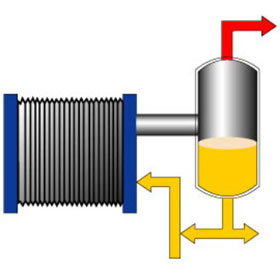

Gravity CirculationCirculating pump is not required because materials would begin to circulate naturally by thermo-siphon. When circulating evaporativity failed to meet the condition, gravity circulation is useful for further evaporation of concentrated materials. In this condition, Plate Evaporator is used as a reboiler in the distillation system. |

|

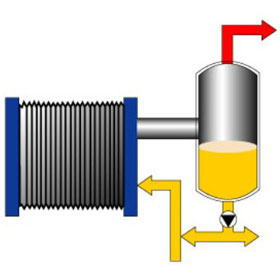

Forced circulation with evaporationThis mold is used when there is fouling tendency of vaporized medium. Forced circulation increases wetting degree and turbulence strength and then decrease fouling tendency to minimum. |

|

Forced circulation with flash heatingThis mold is used when serious fouling or crystallization happen. Vaporized liquid circulates very fast in evaporator so it is just heated without boiled. Actual evaporation starts only when flash heating in separating tank. A special plate evaporator with wider gap will be adopted to decrease the fouling to minimum. |

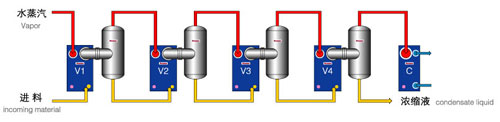

Plate evaporator and plate condenser associate working case |

|

|

We are a professional manufacturer, designer, distributor, and servicer of plate evaporator, plate condenser in China. Our company offers a variety of heat exchanger products, such as plate heat exchanger, spiral heat exchanger, plate and shell heat exchangers, plate evaporator, plate condenser, and plate heat exchanger system. They are widely used in the HVAC, cooling, power, metallurgy, chemical, food, electronics, marine, and environmental industries. Our heat exchangers have been exported to Asia, the Middle East, and Eastern Europe, such as Russia, Ukraine, Poland, Indonesia, Thailand, UAE, Qatar, Saudi Arabia, Pakistan, Bangladesh, Mongolia, India, Iran, Jordan, Venezuela, Macedonia, Singapore and Vietnam. If you need plate evaporator and plate condenser, please don't hesitate to contact us. |