These Plate Evaporator units are developed, designed and manufactured in our well-equipped facilities. Since we can offer both the tubular falling-film evaporator technology and the multi-plate hybrid evaporator technology, we will be in a position to respond to diverse needs with perfect evaporator solutions.

With a tube side, which has a tube-like cross section and is thus similar to the tube-bundle heat exchanger, and a corrugated side with a cross section like that of the plate heat exchanger, this special heat exchanger combines the specific properties and advantages of the two original versions within one single unit.

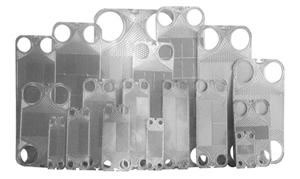

The basic element of any of the plate-type falling-film evaporators is a plate with a constant width of 360 mm. The length of the plate can vary between 216 and 11,880 mm. With plate thicknesses ranging from 0.3 to 1.0 mm, the deformation depth (stamping depth) can be modified with a multi-functional stamping tool within a range of 2.75 and 5.1 mm. Several plates placed one on top of the other and welded together form one heat-exchanger block. A number of these blocks can be connected in series to meet specific performance requirements.

The block of plates thus produced is connected with side plates and tie bars to form a unit of high pressure resistance. The fully-welded plate block can then be welded into any type of pressure-resistant housing.

When assembling the unit with various adapter plates to form a complete plate heat evaporator, the juice chamber and the steam chamber are separated into two distinct sections. The shell placed around the evaporator with the required reinforcements maintains this separation. Each chamber is provided with connections for medium inlet and outlet and with vent and drain sockets.

The juice to be concentrated in the evaporator is fed into the system by a detachable pipe, which passes it to the juice distribution section. This section mainly serves to calm the juice flow, separate solids, and provide for primary and secondary juice distribution. Secondary juice distribution ensures uniform wetting of the tube-shaped plate cross section.

Juice flow through the series-connected plate blocks is from top to bottom, with no additional distribution systems between the blocks. Uniform distribution of the juice is achieved by the large number of tubes about 5,500 per square meter of contact area between the blocks. The thermal energy required to effect phase change in the tube-side juice solution is generated by heating-steam condensation on the corrugated side and by the propelling force of the temperature gradient between the different media.

Since a predefined liquid level is maintained in the vapor chamber at the bottom end of the evaporator, the vapors produced cannot be extracted through the juice outlet socket.

Customer Benefits

· High energy savings potential

· Improved juice colour due to short retention times

· Low investment cost

· Conversion of existing Robert evaporators to provide up to three times the original heating surface

· Excellent system control due to short reaction times

Manufacturer of plating chemicals and custom automated equipment for plating including hoists, reel-to-reel, continuous vertical platers and specialty equipment. Offers a full range of vacuum UHV equipment for thin films and surface technology such as mini electron beam evaporators, plasma sources, sputter sources, effusion cells, hydrogen crackers, MCP microChannel plates. Supplier of high purity materials (sputter targets, evaporation sources) for thin film deposition; remanufactured sputtering and evaporation equipment: replacement parts; sputtering accessories including sputtering cathode.

Designs and manufacturers plate-fin heat exchangers, cold plates, condensers, evaporators, and other heat transfer products for aircraft, military vehicles, and other fuel cell power systems. Regasketing company specialising in the servicing and reconditioning of plate heat exchangers and evaporators. Specializing in industrial and commercial coolers, air conditioners, wet plate, and evaporative coolers.

Dubai, United Arab Emirates. Specializes in electroless nickel and hard chrome plating, with added capabilities for providing galvanizing, tin and copper plating, machining, and finishing services. Distributes a full line of over 60, 000 metal products. These products include galvanized, hot-rolled and cold-finished steel, stainless steel, aluminum, brass, copper, and alloy steel . UK. Specializes in plating and metal finishing, particularly for aluminum, copper, and steel alloys. Includes hard anodizing and wide range of plating capabilities. Site provides details of each service.

Source for SMT stencil supplies. Aluminum frames, polyester screen mesh, foil and mesh bonding adhesives, understencil wiping rolls, stainless steel foil, hot plates, heating elements, and cleaning chemicals. Rolled Metal Products is a processing distributor of stainless steel, aluminum, and cold rolled strip coil. Holding company with subsidiaries which produce aluminum and a broad range of value-added and specialized flat-rolled sheet and plate aluminum products. Owns and operates reduction facility and multi-purpose rolling mill. (Nasdaq: CENX).

Manufacturer of aluminum checkered plate, steel checker plate, tread plate and flooring. Manufacturer of checkered tread plate and embossed tread plate, also perforated metal tread plates made of aluminum, steel and other metal materials. Manufacturer of steel and aluminum chequered plate, tread plate, diamond plate and various perforated and embossed metal sheets.

Plate Heat Exchanger

Plate Heat Exchanger

Gasketed Heat Exchanger

Gasketed Heat Exchanger

Welded Heat Exchanger

Welded Heat Exchanger

Brazed Heat Exchanger

Brazed Heat Exchanger

Spiral Heat Exchanger

Spiral Heat Exchanger

Plate and Shell Heat Exchanger

Plate and Shell Heat Exchanger

Plate Evaporator and Plate Condenser

Plate Evaporator and Plate Condenser

Sub-station System for District Heating and Cooling

Sub-station System for District Heating and Cooling

Maintainance Spare Parts

Maintainance Spare Parts

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System