Extending Capability Into Even Tougher Duties with Welded Heat Exchangers

The Shell and Plate Welded Heat Exchanger is designed as a performance upgrade over shell & tube, block-type welded and brazed aluminum heat exchangers. The exchanger offers high thermal performance with compact size, similar to that of gasketed plate heat exchangers, with low hold-up volume and low installed weight, especially when filled.

Combining field experience with design input from our global R&D operations, this test bed of advanced manufacturing processes and equipment has introduced extended-capability refinements. We are now only beginning to explore the shell & plate exchanger’s potential in ever-more-difficult duties. In addition to design improvements, we have added larger plates and extended-thermal-length oblong plates to the product line.

Designed To Distribute Stress

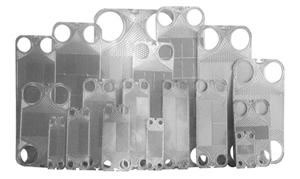

The heart of the Shell & Plate Heat Exchanger is its heat transfer element, also called the plate core, composed of round or oblong chevron-type plates welded into a cassette by a porthole perimeter weld. Cassettes are then placed together welded to each other using a perimeter weld.

The thermal element subassembly then has metal shell-side flow diverters, nozzles and an end plate welded to it. An exclusive cage structure (see picture), welded only to the end cover, surrounds and supports the plate core pack assembly. The cage prevents any cantilever stresses from being transferred to the plate pack. The result is a pressure vessel of high integrity, with an accordion-like core that is highly tolerant of thermal expansion.

The construction is more robust than in gasketed units, shell & tube exchangers and welded block-type square welded units. There are no gaskets to replace or fail. There are no tubes to vibrate under upset flow conditions and induce stress to welds, baffles and supports, with early failure the result. The fully welded round or oblong design, involving both plate port and perimeter welds, is an optimal stress-distributing shape; there are no 90° corners and edges subject to stress failures as with block-type plate heat exchangers.

Field-Proven Durability

Operational durability has been outstanding. Units shipped after passing our factory standard pressure and helium leak tests have logged an extremely low failure rate in the field. Additional available manufacturing process NDEs include:

• Dye penetrant examination (all weld joints)

• X-ray (applicable weld joints)

• UT (applicable weld joints)

• Helium Mass Spectrometer (entire unit)

Duty-Matched Materials

Plate materials may be Type 316L stainless steel, titanium or other alloys; shells may be fabricated of carbon steel, Types 304, 316, 316L stainless and titanium. The unit can be fabricated from dissimilar metals when only one side will be exposed to corrosive conditions.

Designs, sells, and repairs heat exchangers. Includes shell and tube, plate and frame, brazed or welded plate, air cooled, and spiral models. UK. Manufactures broad range of heat exchangers and water heating units. Includes plate, shell and tube, multi scrape, and corrugated tube models. Site provides detailed product information and offers downloadable newsletter. Manufactures broad range of heat transfer equipment for refrigeration, marine, and industrial process applications. Includes shell and tube, plate and frame, and shell and plate heat exchangers, as well as chillers and oil coolers.

Designs, sells, and repairs heat exchangers. Includes shell and tube, plate and frame, brazed or welded plate, air cooled, and spiral models. Manufactures broad range of heat transfer equipment for refrigeration, marine, and industrial process applications. Includes shell and tube, plate and frame, and shell and plate heat exchangers, as well as chillers and oil coolers. Canada. Manufactures brazed plate, plate and frame, and shell and tube heat exchangers for variety of commercial, industrial, and processing applications. Site provides access to downloadable technical and product catalogs.

Manufactures broad range of heat transfer equipment for refrigeration, marine, and industrial process applications. Includes shell and tube, plate and frame, and shell and plate heat exchangers, as well as chillers and oil coolers. Designs and builds shell and tube heat exchangers, primarily for the petroleum refining and petrochemical industries. Gallery and company background included. Canada. Manufactures brazed plate, plate and frame, and shell and tube heat exchangers for variety of commercial, industrial, and processing applications. Site provides access to downloadable technical and product catalogs.

India. Manufacturer of heat exchangers, condensers, reboilers, process equipment, and coils. Materials of construction include stainless steel, carbon steel, alloy steel, nickel, monel, copper. Manufactures a full line of boiler, heat exchanger, mechanical, and custom-engineered tubing products in both carbon and stainless steel. Engineering company who mainly deals with pressure vessels in Stainless steel and Carbon steel, receivers, boilers, process heat exchangers and chemical equipment. India.

India. Manufacturer of heat exchangers, condensers, reboilers, process equipment, and coils. Materials of construction include stainless steel, carbon steel, alloy steel, nickel, monel, copper. Design and manufacture of heat transfer equipment. Products include shell and tube, plate and frame exchangers, heating and cooling coils, tankless coils, oil preheaters, water heaters and tube bundles. Manufacturer of heat transfer products. Includes shell and tube heat exchangers, new and replacement tube bundles, pipe and tube coils, fin coils, tanks and weldments. Photo gallery of products and parts.

Plate Heat Exchanger

Plate Heat Exchanger

Gasketed Heat Exchanger

Gasketed Heat Exchanger

Welded Heat Exchanger

Welded Heat Exchanger

Brazed Heat Exchanger

Brazed Heat Exchanger

Spiral Heat Exchanger

Spiral Heat Exchanger

Plate and Shell Heat Exchanger

Plate and Shell Heat Exchanger

Plate Evaporator and Plate Condenser

Plate Evaporator and Plate Condenser

Sub-station System for District Heating and Cooling

Sub-station System for District Heating and Cooling

Maintainance Spare Parts

Maintainance Spare Parts

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System