The fully-welded plate heat exchanger is widely used in these applications: Oil and Gas Production and Processing, Chemical Processing, Pharmaceutical Industry, Paper Manufacturing, General Industry.

Features

Its fully-welded construction makes it well suited for applications that require the high efficiency and compact size of plate heat exchangers, but where conditions exceed the capabilities of gasketed plate heat exchangers.

Innovative Construction.

The design provides the performance advantages of fully-welded construction, while at the same time providing excellent cleanability.

· The plates are rotated 90° to one another and then welded together to produce two different flow channels.

· The frame is made of four pillars, a bottom plate and a top plate together with four side walls with the connectors.

· All frame components are bolted together and can therefore be easily dismantled to clean and maintain the plate pack.

Design Flexibility.

A number of design factors provide the flexibility that the fully-welded plate heat exchanger is known for.

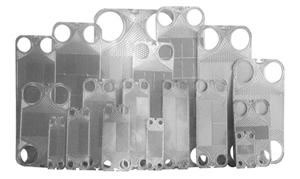

· Two Corrugation Designs. The Chevron design provides higher heat transfer efficiency and the Double Dimple design resists clogging, handles media with particles, and is easily cleaned.

· Several Sizes. Accommodates a wide range of flow rates

· Adjustable Deflectors. Allows easy selection of the right number of passes, for the right balance of heat transfer rate and pressure drop, without compromising cleanability.

· Range of Plate Materials. No matter the media, we've got the right plate material for the application.

Technical Data

· Design Temperature Range: -20°F (-28°C) to 662°F (350°C)

· Maximum Design Pressure: 500 psig (35 barg)

· Plate Material: 316 Stainless Steel as standard. SMO 254, Titanium and others available on request

· Heat Transfer Surface Area: 10-3,400 ft² (1–320 m²)

· Connection Diameter: 2” – 16” (DN50–DN400) as standard

· Maximum Flow Rate: 17,000 gpm (3,860 m³/h)

· Available Corrugation Patterns: Chevron and Double Dimple

Manufactures broad range of heat transfer equipment for refrigeration, marine, and industrial process applications. Includes shell and tube, plate and frame, and shell and plate heat exchangers, as well as chillers and oil coolers. Design and manufacture of heat transfer equipment. Products include shell and tube, plate and frame exchangers, heating and cooling coils, tankless coils, oil preheaters, water heaters and tube bundles. Distributes broad range of heat exchangers. Includes brazed, plate, shell and tube, and spiral models, available in standard and custom configurations. Also sells parts and provides reconditioning services.

Ameridex manufactures plate and frame heat exchangers, plate exchangers, brazed exchangers and specialized heat exchangers. Site includes product descriptions and applications. Canada. Manufactures brazed plate, plate and frame, and shell and tube heat exchangers for variety of commercial, industrial, and processing applications. Site provides access to downloadable technical and product catalogs. Manufactures broad range of heat transfer equipment for refrigeration, marine, and industrial process applications. Includes shell and tube, plate and frame, and shell and plate heat exchangers, as well as chillers and oil coolers.

Manufactures plate and frame, immersion, gasketed, and all-welded plate-type heat exchangers. Additional line comprises transformer radiators and valves. Site includes downloadable product and application information. Aftermarket supplier of heat exchanger plates, gaskets, and other parts. Services include inspection, cleaning, regasketing, replacement parts, frame reconditioning, and special exchange program. Korea. Manufactures broad range of heat exchangers. Includes finned tube, gasketed plate, shell and tube, and spiral models. Also offers recuperators and deaeroators.

Designs and manufacturers plate-fin heat exchangers, cold plates, condensers, evaporators, and other heat transfer products for aircraft, military vehicles, and other fuel cell power systems. Sweden. Manufactures broad range of heat exchangers. Includes brazed and gasketed plate versions, as well as welded models and heating stations. Site provides detailed explanation of heat exchanger types and technology. Manufactures plate and frame, immersion, gasketed, and all-welded plate-type heat exchangers. Additional line comprises transformer radiators and valves. Site includes downloadable product and application information.

Plate Heat Exchanger

Plate Heat Exchanger

Gasketed Heat Exchanger

Gasketed Heat Exchanger

Welded Heat Exchanger

Welded Heat Exchanger

Brazed Heat Exchanger

Brazed Heat Exchanger

Spiral Heat Exchanger

Spiral Heat Exchanger

Plate and Shell Heat Exchanger

Plate and Shell Heat Exchanger

Plate Evaporator and Plate Condenser

Plate Evaporator and Plate Condenser

Sub-station System for District Heating and Cooling

Sub-station System for District Heating and Cooling

Maintainance Spare Parts

Maintainance Spare Parts

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System