Heat transfer occurs when there is a difference in temperature between two mediums. Heat will travel from the hot source to the cold source. The rate at which the heat transfer occurs at is determined by many factors such as the heat conductivity of the two materials and the difference in temperatures of the two mediums. Convective heat transfer occurs when the materials are moving against each other.

The Copper Brazed Plate Heat Exchangers have significantly good heat transfer rates because they use metal plates which have high heat conductivity rates and the plates are extremely thin. The plate heat exchangers also achieve high amounts of heat transfer through convective forces with both working fluids. With large temperature differentials, great amounts of heat transfer can be achieved using a plate heat exchanger.

Corrosion

Corrosion is usually how these units will fail. Use fluids with reasonable pH levels to ensure a long lasting life. Hard water will corrode faster than regular water. (Use distilled if possible; Distilled should never corrode it) Salt water will corrode stainless steel very fast. It is recommended to clean the exchanger often if you are using corrosive fluids. Normal usage (non-corrosive fluids) should expect 10-20 years of life. Fluids containing chlorides will corrode the unit quickly.

Applications

This Copper Brazed Plate Heat Exchanger is an extremely popular unit for wood burning furnaces, radiant floor systems, refrigerant systems, straight vegetable oil conversions, beer chilling, air conditioning system and solar water heating systems. It will work for any application in which the desired result is for two fluids (liquid or gas) to exchange heat.

How It Works?

Fluid A passes from the port on the left of the heat exchanger through every other channel created by the plates to the opposite end port on the left of the heat exchanger (looking at it the long way). Fluid B passes from the port on the right through the other channels created by the plates and comes out the other port on the right side. The fluids are essentially touching each other through the plates and heat is transferred from the hot fluid to the cold fluid. (but the fluids do not mix)

Ameridex manufactures plate and frame heat exchangers, plate exchangers, brazed exchangers and specialized heat exchangers. Site includes product descriptions and applications. Canada. Manufactures brazed plate, plate and frame, and shell and tube heat exchangers for variety of commercial, industrial, and processing applications. Site provides access to downloadable technical and product catalogs. Manufacturer of brazed plate heat exchangers. Applications include heating, cooling, refrigeration, hydronic, steam and industrial processes. Site includes detailed product information.

Fluxes for soldering copper/brass and brazing aluminum for the automotive heat exchanger manufacturing industry. Ameridex manufactures plate and frame heat exchangers, plate exchangers, brazed exchangers and specialized heat exchangers. Site includes product descriptions and applications. Canada. Manufactures brazed plate, plate and frame, and shell and tube heat exchangers for variety of commercial, industrial, and processing applications. Site provides access to downloadable technical and product catalogs.

Manufacture and export worldwide soldering and brazing fluxes and alloys, and different kind of solutions related with water, gas, heat and refrigeration. Manufacturer of brazed plate heat exchangers. Applications include heating, cooling, refrigeration, hydronic, steam and industrial processes. Site includes detailed product information. Fluxes for soldering copper/brass and brazing aluminum for the automotive heat exchanger manufacturing industry.

India. Manufacturer of heat exchangers, condensers, reboilers, process equipment, and coils. Materials of construction include stainless steel, carbon steel, alloy steel, nickel, monel, copper. Fluxes for soldering copper/brass and brazing aluminum for the automotive heat exchanger manufacturing industry. Ameridex manufactures plate and frame heat exchangers, plate exchangers, brazed exchangers and specialized heat exchangers. Site includes product descriptions and applications.

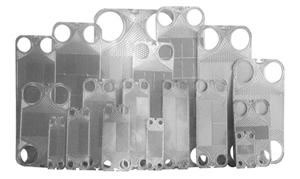

Plate Heat Exchanger

Plate Heat Exchanger

Gasketed Heat Exchanger

Gasketed Heat Exchanger

Welded Heat Exchanger

Welded Heat Exchanger

Brazed Heat Exchanger

Brazed Heat Exchanger

Spiral Heat Exchanger

Spiral Heat Exchanger

Plate and Shell Heat Exchanger

Plate and Shell Heat Exchanger

Plate Evaporator and Plate Condenser

Plate Evaporator and Plate Condenser

Sub-station System for District Heating and Cooling

Sub-station System for District Heating and Cooling

Maintainance Spare Parts

Maintainance Spare Parts

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System

Dezionised Water Cooling Unit For Medium-Voltage AC Drive System